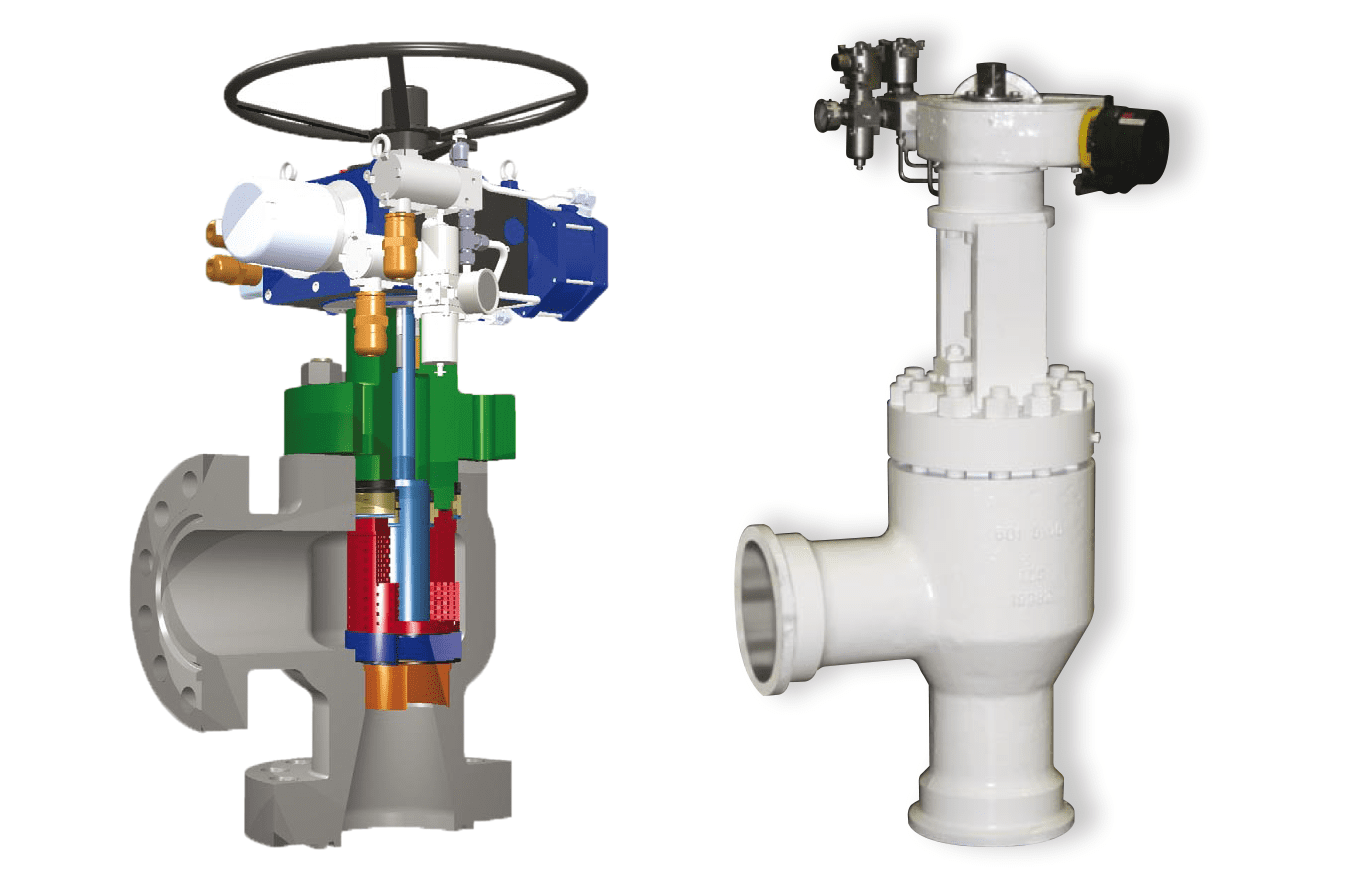

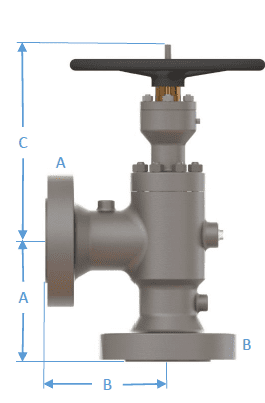

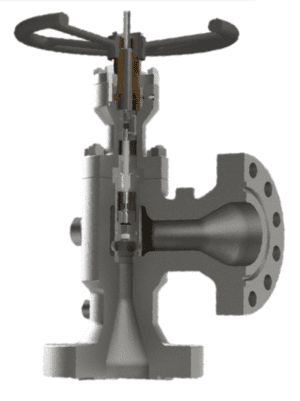

Adjustable Choke Valve

Choke valve, sometimes also known as 'choker valve' is a type of control valve, mostly used in oil and gas production wells to control the flow of well fluids being produced. Another purpose that the choke valves serve is to kill the pressure from reservoir and to regulate the downstream pressure in the flowlines. Choke valves allow fluid flow through a very small opening, designed to kill the reservoir pressure while regulating the well production. The reservoir fluids can contain sand particles. Hence the choke valves are usually designed to handle an erosive service. Typically oil and gas producing wells have two choke valves in series, one non-regulating choke valve and one regulating choke valve downstream to the non-regulating choke valve.